品牌专区

售前咨询:0769-22186189

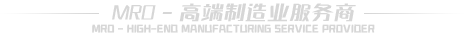

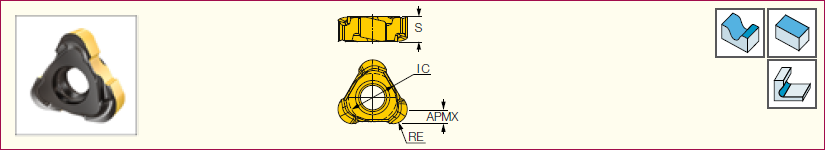

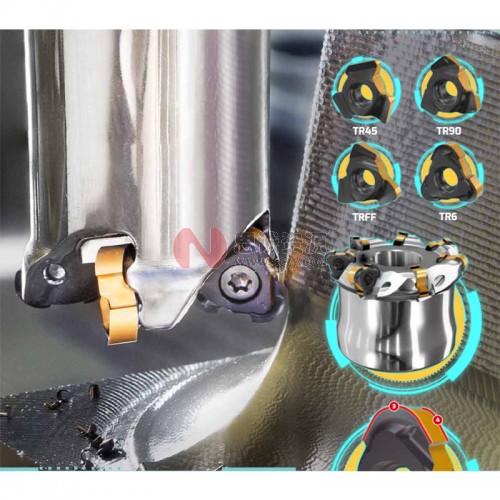

多功能立铣刀,能夹持4种不同性状的刀片。

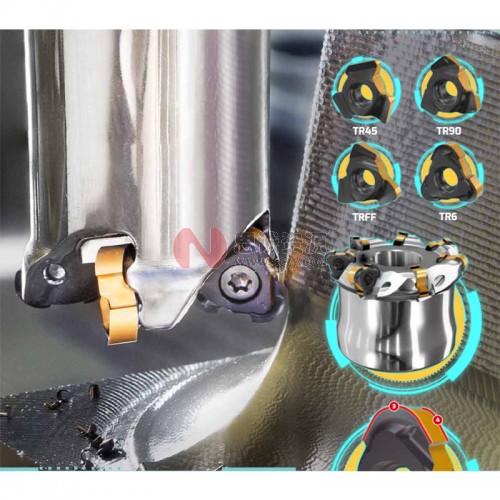

| 型号 | DCX | DC | APMX | APMX_2(1) | RE | CICT(2) | LU | LH | DCONMS | BHTA | OAL | WT(3) | 刀片 |

| TR6 ER D16-50-2-C16-07 | 16.00 | 14.00 | 1.00 | 2.00 | 1.00 | 2 | 46.5 | 50.0 | 16.00 | 21.0 | 100.00 | 0.12 | TR6 TNCU 070210 |

| TR6 ER D20-60-4-C20-07 | 20.00 | 18.00 | 1.00 | 2.00 | 1.00 | 4 | 56.5 | 60.0 | 20.00 | 21.0 | 120.00 | 0.22 | TR6 TNCU 070210 |

| TR6 ER D25-70-5-C25-07 | 25.00 | 23.00 | 1.00 | 2.00 | 1.00 | 5 | 65.5 | 70.0 | 25.00 | 21.0 | 140.00 | 0.42 | TR6 TNCU 070210 |

| TR6 ER D32-80-6-C32-07 | 32.00 | 30.00 | 1.00 | 2.00 | 1.00 | 6 | 75.5 | 80.0 | 32.00 | 21.0 | 160.00 | 0.82 | TR6 TNCU 070210 |

| TR6 ER D25-70-3-C25-10 | 25.00 | 20.00 | 2.50 | 4.20 | 2.50 | 3 | 65.0 | 70.0 | 25.00 | 20.5 | 140.00 | 0.41 | TR6 TNCU 100425 |

| TR6 ER D32-80-4-C32-10 | 32.00 | 27.00 | 2.50 | 4.20 | 2.50 | 4 | 75.0 | 80.0 | 32.00 | 20.5 | 160.00 | 0.81 | TR6 TNCU 100425 |

注:相关数据仅适用于夹持TR6 TNCU 070201及TR6 TNCU 100425刀片时,夹持其他刀尖圆角半径刀片、其他性状刀片时的数据参见下表。

(1)用于清根加工

(2)夹持刀片数

(3)刀具重量

备件

| 型号 | 夹紧螺钉 | 扳手 | ||

| TR6 | ER | D16-50-2-C16-07 | SR M2.5X0.45-L6 IP7 | IP-7/51 |

| TR6 | ER | D20-60-4-C20-07 | SR M2.5X0.45-L6 IP7 | IP-7/51 |

| TR6 | ER | D25-70-5-C25-07 | SR M2.5X0.45-L6 IP7 | IP-7/51 |

| TR6 | ER | D32-80-6-C32-07 | SR M2.5X0.45-L6 IP7 | IP-7/51 |

| TR6 | ER | D25-70-3-C25-10 | SR 10508600 | T-9/51 |

| TR6 | ER | D32-80-4-C32-10 | SR 10508600 | T-9/51 |

| TR6 ER D16-50-2-C16-07 | TR6 TNCU 070205 | 16.0 | 15.0 | 0.5 | 46.4 | 49.9 | 99.9 | - | 1.6 | 17.0 |

| TR6 TNMU 070215 | 13.0 | 1.5 | 45.6 | 50.1 | 100.1 | - | 2.4 | 21.0 | ||

| TRFF TXMT 0702 | 12.1 | 0.6 | 46.7 | 50.2 | 100.2 | 1.1 | - | - | ||

| TR90 TXMT 070204 | - | 2.5 | 46.8 | 50.3 | 100.3 | 1.6 | - | - | ||

| TR6 ER D20-60-4-C20-07 | TR6 TNCU 070205 | 20.0 | 19.0 | 0.5 | 56.4 | 59.9 | 119.9 | - | 1.6 | 17.0 |

| TR6 TNMU 070215 | 17.0 | 1.5 | 56.6 | 60.1 | 120.1 | - | 2.4 | 21.0 | ||

| TRFF TXMT 0702 | 16.1 | 0.6 | 56.7 | 60.2 | 120.2 | 0.8 | - | - | ||

| TR90 TXMT 070204 | - | 2.5 | 56.8 | 60.3 | 120.3 | 1.2 | - | - | ||

| TR6 ER D25-70-5-C25-07 | TR6 TNCU 070205 | 25.0 | 24.0 | 1.0 | 65.4 | 69.9 | 139.9 | - | 1.6 | 17.0 |

| TR6 TNMU 070215 | 22.0 | 1.5 | 65.6 | 70.1 | 140.1 | - | 2.4 | 21.0 | ||

| TRFF TXMT 0702 | 21.1 | 0.6 | 65.7 | 70.2 | 140.2 | 0.6 | - | - | ||

| TR90 TXMT 070204 | - | 2.5 | 65.8 | 70.3 | 140.3 | 0.9 | - | - | ||

| TR6 ER D32-80-6-C32-07 | TR6 TNCU 070205 | 32.0 | 31.0 | 0.5 | 75.4 | 79.9 | 159.9 | - | 1.6 | 17.0 |

| TR6 TNMU 070215 | 29.0 | 1.5 | 75.6 | 80.1 | 160.1 | - | 2.4 | 21.0 | ||

| TRFF TXMT 0702 | 28.1 | 0.6 | 75.7 | 80.2 | 160.2 | 0.4 | - | - | ||

| TR90 TXMT 070204 | - | 2.5 | 75.8 | 80.3 | 160.3 | 0.7 | - | - | ||

| TR6 ER D25-70-3-C25-10 | TR6 TNCU 100405 | 25 | 24.0 | 0.5 | 64.5 | 69.5 | 139.5 | - | 1.8 | 17.5 |

| TR6 TNCU 100410 | 23.0 | 1.0 | 64.6 | 69.6 | 139.7 | - | 2.3 | 20.5 | ||

| TR6 TNCU/MU 100415 | 22.0 | 1.5 | 64.76 | 69.76 | 139.76 | - | 2.7 | |||

| TR6 TNCU 100420 | 21.0 | 2.0 | 64.9 | 69.9 | 139.9 | - | 3.5 | |||

| TR6 TNCU 100430 | 19.0 | 3 | 65.12 | 70.12 | 140.12 | - | 4.5 | |||

| TRFF TXMT 1004 | 19.0 | 0.8 | 65.2 | 70.2 | 140.2 | 1.7 | - | |||

| TR90 TXMT 100408 | - | 4 | 64.91 | 69.91 | 139.91 | 1.6 | - | |||

| TR45 TXMT 1004 | 26.8 | 20.6 | 3 | 65.12 | 70.12 | 140.12 | 1.4 | - | ||

| TR6 ER D32-80-4-C32-10 | TR6 TNCU 100405 | 32 | 31.0 | 0.5 | 74.5 | 79.5 | 159.5 | - | 1.8 | 17.5 |

| TR6 TNCU 100410 | 30.0 | 1.0 | 74.6 | 79.7 | 159.6 | - | 2.3 | 20.5 | ||

| TR6 TNCU/MU 100415 | 29.0 | 1.5 | 76.76 | 79.76 | 159.76 | - | 2.7 | |||

| TR6 TNCU 100420 | 28.0 | 2.0 | 74.9 | 79.9 | 159.9 | - | 3.5 | |||

| TR6 TNCU 100430 | 26.0 | 3 | 75.12 | 80.12 | 160.12 | - | 4.5 | |||

| TRFF TXMT 1004 | 26.0 | 0.8 | 75.2 | 80.2 | 160.2 | 1.2 | - | |||

| TR90 TXMT 100408 | - | 4 | 74.91 | 79.91 | 159.91 | 1.2 | - | |||

| TR45 TXMT 1004 | 33.8 | 27.6 | 3 | 75.12 | 80.12 | 160.12 | 1 | - |

(1)最大坡走铣角度

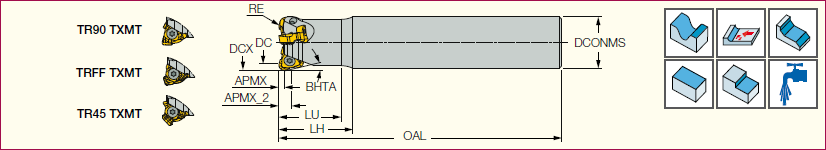

TR6 ER-M

FLEXFIT模块螺纹连接式多功能立铣刀

能夹持4种不同性状的刀片

| 型号 | DCX | DC | APMX | APMX_2(1) | RE | CICT(2) | LF | DCONMS | THSZMS | BHTA | OAL | WT(3) | 刀片 |

| TR6 ER D16/0.63-2-M08-07 | 16 | 14 | 1 | 2 | 1 | 2 | 20 | 13 | M08 | 21 | 37.5 | 0.03 | TR6 TNCU 070210 |

| TR6 ER D25/0.98-5-M12-07 | 25 | 23 | 1 | 2 | 1 | 5 | 30 | 21 | M12 | 21 | 52 | 0.08 | TR6 TNCU 070210 |

| TR6 ER D32/1.26-6-M16-07 | 32 | 30 | 1 | 2 | 1 | 6 | 35 | 29 | M16 | 21 | 60 | 0.18 | TR6 TNCU 070210 |

| TR6 ER D35/1.38-6-M16-07 | 35 | 33 | 1 | 2 | 1 | 6 | 35 | 29 | M16 | 21 | 60 | 0.19 | TR6 TNCU 070210 |

| TR6 ER D25/0.98-3-M12-10 | 25 | 20 | 2.5 | 4.2 | 2.5 | 3 | 35 | 21 | M12 | 20.5 | 57 | 0.06 | TR6 TNCU 100425 |

| TR6 ER D35/1.38-5-M16-10 | 35 | 30 | 2.5 | 4.2 | 2.5 | 5 | 35 | 29 | M16 | 20.5 | 57 | 0.18 | TR6 TNCU 100425 |

注:相关数据仅适用于夹持TR6 TNCU 080201及TR6 TNCU 100425刀片时,夹持其他刀尖圆角半径刀片、其他性状刀片时的数据参见下表

(1)用于清根加工

(2)夹持刀片数

(3)刀具重量

备件

| 型号 | 夹紧螺钉 | 扳手 | ||

| TR6 | ER | D16/0.63-2-M08-07 | SR M2.5X0.45-L6 IP7 | IP-7/51 |

| TR6 | ER | D25/0.98-5-M12-07 | SR M2.5X0.45-L6 IP7 | IP-7/51 |

| TR6 | ER | D32/1.26-6-M16-07 | SR M2.5X0.45-L6 IP7 | IP-7/51 |

| TR6 | ER | D35/1.38-6-M16-07 | SR M2.5X0.45-L6 IP7 | IP-7/51 |

| TR6 | ER | D25/0.98-3-M12-10 | SR 10508600 | T-9/51 |

| TR6 | ER | D35/1.38-5-M16-10 | SR 10508600 | T-9/51 |

| 用于清根加工 | |||||||||

| 铣刀 | 刀片 | DCX | DC | APMX | LF | OAL | RMPX | APMX_2 | BHTA |

| TR6 ER D16/0.63-2-M08-07 | TR6 TNCU 070205 | 16.0 | 15.0 | 0.5 | 24.9 | 42.4 | - | 1.6 | 17.0 |

| TR6 TNMU 070215 | 13.0 | 1.5 | 25.1 | 42.6 | - | 2.4 | 21.0 | ||

| TRFF TXMT 0702 | 12.1 | 0.6 | 25.2 | 47.2 | 1.1 | - | - | ||

| TR90 TXMT 070204 | - | 2.5 | 25.3 | 42.8 | 1.6 | - | - | ||

| TR6 ER D20/0.78-4-M10-07 | TR6 TNCU 070205 | 20.0 | 19.0 | 0.5 | 26.9 | 46.9 | - | 1.6 | 17.0 |

| TR6 TNMU 070215 | 17.0 | 1.5 | 27.1 | 47.1 | - | 2.4 | 21.0 | ||

| TRFF TXMT 0702 | 16.1 | 0.6 | 27.2 | 47.2 | 0.8 | - | - | ||

| TR90 TXMT 070204 | - | 2.5 | 27.3 | 47.3 | 1.2 | - | - | ||

| TR6 ER D25/0.98-5-M12-07 | TR6 TNCU 070205 | 25 | 24.0 | 0.5 | 29.9 | 51.9 | - | 1.6 | 17.0 |

| TR6 TNMU 070215 | 22.0 | 1.5 | 30.1 | 52.1 | - | 2.4 | 21.0 | ||

| TRFF TXMT 0702 | 21.1 | 0.6 | 30.2 | 52.2 | 0.6 | - | - | ||

| TR90 TXMT 070204 | - | 2.5 | 30.3 | 52.3 | 0.9 | - | - | ||

| TR6 ER D32/1.26-6-M16-07 | TR6 TNCU 070205 | 32.0 | 31.0 | 0.5 | 32.9 | 57.9 | - | 1.6 | 17.0 |

| TR6 TNMU 070215 | 29.0 | 1.5 | 33.1 | 58.1 | - | 2.4 | 21.0 | ||

| TRFF TXMT 0702 | 28.1 | 0.6 | 33.2 | 58.2 | 0.4 | - | - | ||

| TR90 TXMT 070204 | - | 2.5 | 33.3 | 58.3 | 0.7 | - | - | ||

| TR6 ER D35/1.38-6-M16-07 | TR6 TNCU 070205 | 35 | 34 | 0.5 | 32.9 | 57.9 | - | 1.6 | 17 |

| TR6 TNMU 070215 | 32 | 1.5 | 33.1 | 58.1 | - | 2.4 | 21 | ||

| TRFF TXMT 0702 | 31.1 | 0.6 | 33.2 | 58.2 | 0.4 | - | - | ||

| TR90 TXMT 070204 | - | 2.5 | 33.3 | 58.3 | 0.4 | - | - | ||

| TR6 ER D25/0.98-3-M12-10 | TR6 TNCU 100405 | 25 | 24 | 0.5 | 24.52 | 46.52 | - | 1.8 17.5 | 17.5 |

| TR6 TNCU 100410 | 23 | 1 | 24.64 | 46.64 | - | 2.3 | 20.5 | ||

| TR6 TNCU/MU 100415 | 22 | 1.5 | 24.76 | 46.76 | - | 2.7 | |||

| TR6 TNCU 100420 | 21 | 2 | 24.88 | 46.88 | - | 3.5 | |||

| TR6 TNCU 100430 | 19 | 3 | 25.12 | 47.12 | - | 4.5 | |||

| TRFF TXMT 1004 | 20.6 | 0.8 | 25.15 | 47.15 | 1.7 | ||||

| TR90 TXMT 100408 | - | 4 | 24.91 | 46.91 | 1.6 | - | |||

| TR45 TXMT 1004 | 26.8 | 20.6 | 3 | 25.12 | 47.12 | 1.4 | - | ||

| TR6 ER D32/1.26-4-M16-10 | TR6 TNCU 100405 | 32 | 31 | 0.5 | 34.52 | 59.52 | - | 1.8 | 17.5 |

| TR6 TNCU 100410 | 30 | 1 | 34.64 | 59.64 | - | 2.3 | 20.5 | ||

| TR6 TNCU/MU 100415 | 29 | 1.5 | 34.76 | 59.76 | - | 2.7 | |||

| TR6 TNCU 100420 | 28 | 2 | 34.88 | 59.88 | - | 3.5 | |||

| TR6 TNCU 100430 | 26 | 3 | 35.12 | 60.12 | - | 4.5 | |||

| TRFF TXMT 1004 | 27.6 | 0.8 | 35.15 | 60.15 | 1.2 | - | |||

| TR90 TXMT 100408 | - | 4 | 34.91 | 59.91 | 1.1 | - | |||

| TR45 TXMT 1004 | 33.8 | 27.6 | 3 | 35.12 | 60.12 | 0.9 | - | ||

| TR6 ER D35/1.38-5-M16-10 | TR6 TNCU 100405 | 35 | 34 | 0.5 | 34.52 | 59.52 | - | 1.8 | 17.5 |

| TR6 TNCU 100410 | 33 | 1 | 34.64 | 59.64 | - | 2.3 | 20.5 | ||

| TR6 TNCU/MU 100415 | 32 | 1.5 | 34.76 | 59.76 | - | 2.7 | |||

| TR6 TNCU 100420 | 31 | 2 | 34.88 | 59.88 | - | 3.5 | |||

| TR6 TNCU 100430 | 29 | 3 | 35.12 | 60.12 | - | 4.5 | |||

| TRFF TXMT 1004 | 30.6 | 0.8 | 35.15 | 60.15 | 1.2 | - | |||

| TR90 TXMT 100408 | - | 4 | 34.91 | 59.91 | 1.1 | - | |||

| TR45 TXMT 1004 | 36.8 | 30.6 | 3 | 35.12 | 60.12 | 0.9 | - | ||

TR6 FR

多功能面铣刀,能夹持4种不同性状的刀片

| 型号 | DCX | DC | APMX | APMX_2(1) | RE | CICT(2) | DCONMS | 心轴类型 | DHUB | BHTA | OAL | WT(3) | 刀片 |

| TR6 FR D40-06-16-10 | 40.00 | 35.00 | 2.50 | 4.20 | 2.50 | 6 | 16.00 | A | 32.00 | 20.5 | 37.00 | 0.14 | TR6 TNCU 100425 |

| TR6 FR D42-06-16-10 | 42.00 | 37.00 | 2.50 | 4.20 | 2.50 | 6 | 16.00 | A | 32.00 | 20.5 | 37.00 | 0.15 | TR6 TNCU 100425 |

| TR6 FR D50-07-22-10 | 50.00 | 45.00 | 2.50 | 4.20 | 2.50 | 7 | 22.00 | A | 47.00 | 20.5 | 40.00 | 0.29 | TR6 TNCU 100425 |

| TR6 FR D52-07-22-10 | 52.00 | 47.00 | 2.50 | 4.20 | 2.50 | 7 | 22.00 | A | 47.00 | 20.5 | 40.00 | 0.33 | TR6 TNCU 100425 |

| TR6 FR D63-08-22-10 | 63.00 | 58.00 | 2.50 | 4.20 | 2.50 | 8 | 22.00 | A | 48.00 | 20.5 | 40.00 | 0.42 | TR6 TNCU 100425 |

| TR6 FR D66-08-22-10 | 66.00 | 61.00 | 2.50 | 4.20 | 2.50 | 8 | 22.00 | A | 48.00 | 20.5 | 40.00 | 0.46 | TR6 TNCU 100425 |

| TR6 FR D80-10-27-10 | 80.00 | 75.00 | 2.50 | 4.20 | 2.50 | 10 | 27.00 | A | 60.00 | 20.5 | 50.00 | 0.91 | TR6 TNCU 100425 |

注:相关数据仅适用于夹持TR6 TNCU 100425刀片时,夹持其他刀尖圆角半径刀片、其它性状刀片时的数据参见下表。

(1)用于清根加工

(2)夹持刀片数

(3)刀具重量

备件

| 型号 | Screw | Key | Screw 1 |

| TR6 FR D40-06-16-10 | SR 10508600 | T-9/51 | SR M8X25DIN912* |

| TR6 FR D42-06-16-10 | SR 10508600 | T-9/51 | SR M8X25DIN912* |

| TR6 FR D50-07-22-10 | SR 10508600 | T-9/51 | SR M10X25 DIN912 |

| TR6 FR D52-07-22-10 | SR 10508600 | T-9/51 | SR M10X25 DIN912 |

| TR6 FR D63-08-22-10 | SR 10508600 | T-9/51 | SR M10X25 DIN912 |

| TR6 FR D66-08-22-10 | SR 10508600 | T-9/51 | SR M10X25 DIN912 |

| TR6 FR D80-10-27-10 | SR 10508600 | T-9/51 | SR M12X30DIN912 |

*可选,需单独订购。

| 用于清根加工 | ||||||||

| 铣刀 | Insert | DCX | DC | APMX | OAL | RMPX | APMX_2 | BHTA |

| TR6 FR D40-06-16-10 | TR6 TNCU 100405 | 40 | 39 | 0.5 | 36.52 | - | 1.8 | 17.5 |

| TR6 TNCU 100410 | 38 | 1 | 36.64 | - | 2.3 | 20.5 | ||

| TR6 TNCU/MU 100415 | 37 | 1.5 | 36.76 | - | 2.7 | |||

| TR6 TNCU 100420 | 36 | 2 | 36.88 | - | 3.5 | |||

| TR6 TNCU 100430 | 34 | 3 | 37.12 | - | 4.5 | |||

| TRFF TXMT 1004 | 34 | 0.8 | 37.15 | 0.9 | - | |||

| TR90 TXMT 100408 | - | 4 | 36.91 | 0.9 | - | |||

| TR45 TXMT 1004 | 41.8 | 35.6 | 3 | 37.12 | 0.7 | - | ||

| TR6 FR D42-06-16-10 | TR6 TNCU 100405 | 42 | 41 | 0.5 | 36.52 | - | 1.8 | 17.5 |

| TR6 TNCU 100410 | 40 | 1 | 36.64 | - | 2.3 | 20.5 | ||

| TR6 TNCU/MU 100415 | 39 | 1.5 | 36.76 | - | 2.7 | |||

| TR6 TNCU 100420 | 38 | 2 | 36.88 | - | 3.5 | |||

| TR6 TNCU 100430 | 36 | 3 | 37.12 | - | 4.5 | |||

| TRFF TXMT 1004 | 36 | 0.8 | 37.15 | 0.9 | - | |||

| TR90 TXMT 100408 | - | 4 | 36.91 | 0.9 | - | |||

| TR45 TXMT 1004 | 43.8 | 37.6 | 3 | 37.12 | 0.7 | - | ||

| TR6 FR D50-07-22-10 | TR6 TNCU 100405 | 50 | 49 | 0.5 | 39.52 | - | 1.8 | 17.5 |

| TR6 TNCU 100410 | 48 | 1 | 39.64 | - | 2.3 | 20.5 | ||

| TR6 TNCU/MU 100415 | 47 | 1.5 | 39.76 | - | 2.7 | |||

| TR6 TNCU 100420 | 46 | 2 | 39.88 | - | 3.5 | |||

| TR6 TNCU 100430 | 44 | 3 | 40.12 | - | 4.5 | |||

| TRFF TXMT 1004 | 44 | 0.8 | 40.15 | 0.7 | - | |||

| TR90 TXMT 100408 | - | 4 | 39.91 | 0.7 | - | |||

| TR45 TXMT 1004 | 51.8 | 45.6 | 3 | 40.12 | 0.6 | - | ||

| TR6 FR D52-07-22-10 | TR6 TNCU 100405 | 52 | 51 | 0.5 | 39.52 | - | 1.8 | 17.5 |

| TR6 TNCU 100410 | 50 | 1 | 39.64 | - | 2.3 | 20.5 | ||

| TR6 TNCU/MU 100415 | 49 | 1.5 | 39.76 | - | 2.7 | |||

| TR6 TNCU 100420 | 48 | 2 | 39.88 | - | 3.5 | |||

| TR6 TNCU 100430 | 46 | 3 | 40.12 | - | 4.5 | |||

| TRFF TXMT 1004 | 46 | 0.8 | 40.15 | 0.7 | - | |||

| TR90 TXMT 100408 | - | 4 | 39.91 | 0.7 | - | |||

| TR45 TXMT 1004 | 53.8 | 53.8 | 3 | 40.12 | 0.6 | - | ||

| TR6 FR D63-08-22-10 | TR6 TNCU 100405 | 63 | 62 | 0.5 | 39.52 | - | 1.8 | 17.5 |

| TR6 TNCU 100410 | 61 | 1 | 39.64 | - | 2.3 | 20.5 | ||

| TR6 TNCU/MU 100415 | 60 | 1.5 | 39.76 | - | 2.7 | |||

| TR6 TNCU 100420 | 59 | 2 | 39.88 | - | 3.5 | |||

| TR6 TNCU 100430 | 57 | 3 | 40.12 | - | 4.5 | |||

| TRFF TXMT 1004 | 57 | 0.8 | 40.15 | 0.5 | - | |||

| TR90 TXMT 100408 | - | 4 | 39.91 | 0.5 | - | |||

| TR45 TXMT 1004 | 64.8 | 58.6 | 3 | 40.12 | 0.4 | - | ||

| TR6 FR D66-08-22-10 | TR6 TNCU 100405 | 66 | 65 | 0.5 | 39.52 | - | 1.8 | 17.5 |

| TR6 TNCU 100410 | 64 | 1 | 39.64 | - | 2.3 | 20.5 | ||

| TR6 TNCU/MU 100415 | 63 | 1.5 | 39.76 | - | 2.7 | |||

| TR6 TNCU 100420 | 62 | 2 | 39.88 | - | 3.5 | |||

| TR6 TNCU 100430 | 60 | 3 | 40.12 | - | 4.5 | |||

| TRFF TXMT 1004 | 60 | 0.8 | 40.15 | 0.5 | - | |||

| TR90 TXMT 100408 | - | 4 | 39.91 | 0.5 | - | |||

| TR45 TXMT 1004 | 67.8 | 61.6 | 3 | 40.12 | 0.4 | - | ||

| TR6 FR D80-10-27-10 | TR6 TNCU 100405 | 80 | 79 | 0.5 | 49.52 | - | 1.8 | 17.5 |

| TR6 TNCU 100410 | 78 | 1 | 49.64 | - | 2.3 | 20.5 | ||

| TR6 TNCU/MU 100415 | 77 | 1.5 | 49.76 | - | 2.7 | |||

| TR6 TNCU 100420 | 76 | 2 | 49.88 | - | 3.5 | |||

| TR6 TNCU 100430 | 74 | 3 | 50.12 | - | 4.5 | |||

| TRFF TXMT 1004 | 74 | 0.8 | 50.15 | 0.4 | - | |||

| TR90 TXMT 100408 | - | 4 | 49.91 | 0.4 | - | |||

| TR45 TXMT 1004 | 81.8 | 75.6 | 3 | 50.12 | 0.3 | - | ||

刀尖圆角半径从0.5mm到3.0mm

| 型号 | 尺寸 | 韧性 ↔ 耐磨性 | 推荐切削参数 | |||||||||

| RE | APMX | IC | S | IC882 | IC830 | IC808 | IC908 | ap (mm) | fz (mm/t) | |||

| TR6 | TNCU 070205 | 0.50 | 0.50 | 5.30 | 2.80 | • | • | 0.20-0.50 | 0.10-0.30 | |||

| TR6 | TNCU 070210 | 1.00 | 1.00 | 5.30 | 2.80 | • | • | 0.20-1.00 | 0.10-0.30 | |||

| TR6 | TNMU 070215 | 1.50 | 1.50 | 5.30 | 2.80 | • | • | 0.20-1.50 | 0.10-0.30 | |||

| TR6 | TNCU 100405 | 0.50 | 0.50 | 7.30 | 4.20 | • | • | • | 0.20-0.50 | 0.10-0.30 | ||

| TR6 | TNCU 100410 | 1.00 | 1.00 | 7.30 | 4.20 | • | • | • | 0.20-1.00 | 0.10-0.30 | ||

| TR6 | TNCU 100415 | 1.50 | 1.50 | 7.30 | 4.20 | • | • | • | 0.20-1.50 | 0.10-0.30 | ||

| TR6 | TNMU 100415 | 1.50 | 1.50 | 7.30 | 4.20 | • | • | 0.20-1.50 | 0.10-0.30 | |||

| TR6 | TNCU 100420 | 2.00 | 2.00 | 7.30 | 4.20 | • | • | • | 0.20-2.00 | 0.10-0.30 | ||

| TR6 | TNCU 100425 | 2.50 | 2.50 | 7.30 | 4.20 | • | • | • | • | 0.20-2.50 | 0.10-0.30 | |

| TR6 | TNCU 100430 | 3.00 | 3.00 | 7.30 | 4.20 | • | • | • | 0.20-3.00 | 0.10-0.30 | ||

| 型号 | 尺寸 | 韧性 ↔ 耐磨性 | 推荐切削参数 | |||||

| APMX | RE | IC | S | IC830 | IC808 | ap (mm) | fz (mm/t) | |

| TR90 TXMT 070204 | 2.50 | 0.40 | 5.30 | 2.40 | • | • | 0.50-2.50 | 0.10-0.20 |

| TR90 TXMT 100408 | 4.00 | 0.80 | 7.30 | 3.90 | • | • | 0.90-4.00 | 0.10-0.20 |

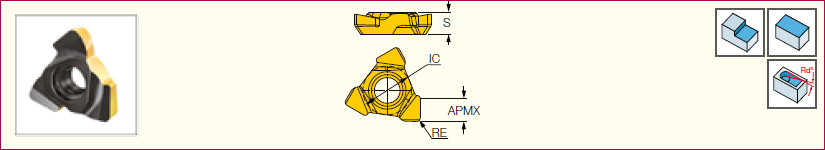

用于大进给铣削

| 型号 | 尺寸 | 韧性↔耐磨性 | 推荐切削参数 | ||||||||

| APMX | RE | Rg(1) | IC | S | KRINS(2) | IC830 | IC808 | ap (mm) | fz (mm/t) | ||

| TRFF TXMT 0702 | 0.60 | 0.50 | 1.00 | 5.30 | 2.40 | 18.0 | • | • | 0.20-0.60 | 0.50-0.80 | |

| TRFF TXMT 1004 | 0.80 | 0.70 | 1.40 | 7.30 | 3.90 | 17.0 | • | • | 0.20-0.80 | 0.70-1.20 | |

(1)编程半径(2)切削刃与修光刃夹角

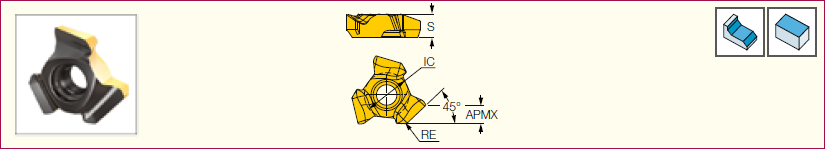

TR45 TXMT

带3个切削刃的单面刀片,用于45°倒角铣及面铣加工

| 型号 | 尺寸 | 韧性↔耐磨性 | 推荐切削参数 | ||||||

| APMX | RE | IC | S | IC830 | IC808 | ap (mm) | fz (mm/t) | ||

| TR45 TXMT 1004 | 3.00 | 0.40 | 7.30 | 3.90 | • | • | 1.00-3.00 | 0.20-0.40 | |

型号:DN50AD-CTH20/CTH25

型号:DN40AD-CTH20/CTH25

型号:BT50-CTH10/CTH20/CTH25/CTH32

型号:BT40-CTH10/CTH20/CTH25

品牌:MST(恩司迪)

型号:BT40-CTH10/CTH20/CTH25